Rockwheel Drum Cutter vs Xcentric Ripper vs Hydraulic Hammer

Every project is different. Ground conditions, production goals, vibration limitations, and material-handling needs all influence which excavator attachment will deliver the best performance. Contractors often compare three reliable tools for rock and concrete work: the Rockwheel drum cutter, the Xcentric Ripper, and the hydraulic hammer. Each attachment excels in specific scenarios, and selecting the right one can significantly improve job speed, equipment longevity, and overall project economics. This guide breaks down how each tool works, where it performs best, and what to watch out for.

How Each Attachment Works

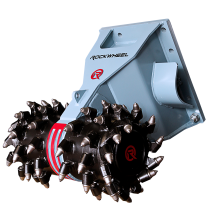

RockZone Rockwheel Drum Cutter (Twin-Drum, Axial, Trench Cutters)

The Rockwheel uses durable carbide teeth to grind rock, concrete, and asphalt into a fine, uniform material. It is ideal for trenching, utility installation, rock walls, and demolition near structures or in vibration-sensitive environments. Rockwheels deliver precise, controlled cuts with clean trench walls and minimal overbreak while producing reusable material that often eliminates the need for imported backfill.

Xcentric Ripper

The Xcentric Ripper is a high-frequency vibration ripper engineered to exploit natural rock fractures. It excels in fractured, layered, or medium-hard geology such as shale, limestone, and sedimentary formations. It is also unmatched in frozen ground and permafrost. The Xcentric Ripper delivers high production with lower vibration, less machine stress, and lower fuel consumption than a hydraulic hammer.

Hydraulic Hammer (Breaker)

A hydraulic hammer is a high-impact percussive tool that strikes rock or concrete with repeated blows. It is the best choice for dense, unfractured rock and heavily reinforced concrete. Hydraulic hammers are familiar to most operators and effective for precise spot-breaking, structural demolition, and boulder reduction. They produce larger fragments that may require secondary breaking or hauling.

Strengths, Weaknesses & Best Use Cases

Quick Selection Guide

| Condition | Recommended Attachment |

|---|---|

| For Precision | ›Rockwheel Drum Cutter |

| For Fractured or Layered Rock | ›Xcentric Ripper |

| For Dense, Massive Rock | ›Hydraulic Hammer |

| If Backfill is needed | ›Rockwheel Drum Cutter |

| For Maximum Production | ›Xcentric Ripper (fractured or frozen ground) ›Hydraulic Hammer (hard, solid rock) |

| For vibration-sensitive areas | ›Rockwheel Drum Cutter |

| For Utility Trenching | ›Rockwheel Drum Cutter |

Why Each Tool Belongs in a Contractor’s Fleet

Rockwheel Drum Cutter

Rockwheels provide unmatched precision, predictable trench widths, reduced overbreak, and extremely low vibration. They are ideal for utility work, rock walls, and trenching where accuracy matters. The fine, uniform material they produce often reduces disposal trips and eliminates the need for imported backfill.

Xcentric Ripper

The Xcentric Ripper offers exceptional production in fractured geology and is industry-leading in frozen ground and permafrost. It lowers fuel consumption, reduces machine wear, and helps contractors move large volumes of material quickly and efficiently.

Hydraulic Hammer

Hydraulic hammers remain essential for the toughest materials on site. They excel in reinforced concrete, dense rock, and precision breaking. Their versatility and operator familiarity make them indispensable on many job sites.

Final Thoughts

Each attachment has its place, and the right choice depends on your material, project goals, and site conditions.

The Rockwheel is the precision specialist.

The Xcentric Ripper is the productivity leader in fractured and frozen ground.

The hydraulic hammer is the heavy hitter for dense rock and reinforced concrete.

Ultimately, the best way to select the right tool is to speak directly with the ShearForce Equipment sales team. Our specialists work with contractors across Canada every day and can evaluate your ground conditions, excavator size, production targets, and budget to recommend the perfect attachment for your project!

Got a question?

We’re here to help you pick out the best tool that suits your unique needs.